The origins of LEAN and LEAN Construction.

While there are many variants of LEAN methodology, they all focus on the delivery of best value outcomes and minimizing waste.

LEAN was first applied in production management, beginning Henry Ford and automobile manufacturing. The history of LEAN manufacturing begins with Ford and his ground-breaking automobile manufacturing company in the early 20th century. Students of LEAN history should begin with the Ford manufacturing plant in Highland Park, Michigan, USA., in 1913. It was there that Ford manufactured the Model T. Ford’s focus was not on organizational structure, but simply on making the best product possible. To do so, he relentlessly pursued methods that eliminated waste and helped employees work more efficiently. He did not focus on making people work harder. He wanted people, and his company as a whole, to work smarter. He had an admirable ability to see the “flow” associated with a process. In Ford’s case, that flow started with raw materials and ended with a customer driving away in a new car. His integration of individual parts, human effort and moving conveyance marked the first time that LEAN principles were put into practice. Essentially, Ford invented them. LEAN production was then used by Toyota in Japan after the second world war via the Toyota Production System. It was later recognized that production principles could be applied to other business activities.

LEAN methods have developed significantly and expanded to most business sectors, including construction and facilities management.

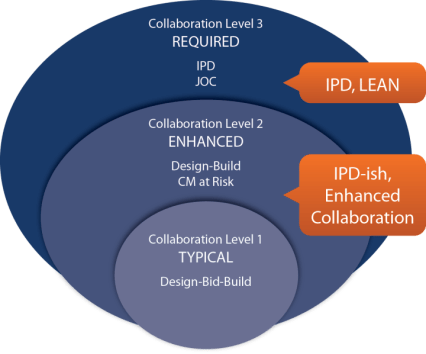

The term ‘LEAN Construction’ is an adaptation of LEAN production techniques applied to the construction industry. Very broadly it can be characterized as techniques aimed at maximizing value and minimizing waste. Robust implementations such ad Integrated Project Delivery, IPD, for major new construction, and Job Order Contracting, JOC, for repair, renovation, and minor new construction, have subsequently been implemented for decades.

LEAN Construction Delivery Methods have proven to consistently improve productivity and quality as well as reduce waste, lower cost and speed delivery. It‘s the owner’s responsibility to provide leadership, and drive the process, this is done within an atmosphere of collaboration and mutual benefit. As noted, most widely used methods of LEAN construction are Integrated Project Delivery, IPD, for major new construction, and Job Order Contracting, JOC, for repair, renovation, and minor new construction. Tools, training, services, and support are readily available for any real property owner to drive consistent on-time, on-budget, quality construction outcomes.

Despite the proven benefits of LEAN construction, deployment has been limited to a small fraction (5% or less) of the industry. This is largely due to the cultural changes required for initial adoption and ongoing execution. LEAN construction requires fundamental changes in how people interact on a day to day basis.

Job Order Contracting has been used most extensively and successfully across the DOD Federal Government Sector. It is now expanding somewhat into non-DOD Federal Government, County/State/Local Government, Transportation, Healthcare, Education, and Utility sectors.

Core tenants of LEAN construction

-

Collaboration – among all participants throughout the project life-cycle (Owners, Architects, Engineers, Contractors…)

-

Long-term relationships – 3-5 years+

-

Focus upon best value

-

Shared risk/reward

-

Financial Transparency

-

Standardized Data Formats / Common Data Environment (CDE)

-

Early and ongoing information sharing

-

Common terms, definitions, and data formats

-

Monitoring & Continuous Improvement

-

Reliance upon participants’ expertise

LEAN construction LIMITS VARIATION by requiring collaboration and transparency, and leveraging the disparate expertise of team members throughout the process, thus assuring high levels of predictability.

An example of how variation is controlled, it ths use of a unit price book, UPB. Job order contracting uses a Unit Price Book, a detailed line item description of construction tasks and associated pricing. A high level of granularity is provided, including associated labor, material, and equipment costs. Common industry terms and definitions are used as well as standard data architecture (Masterformat). While not “perfect”, the UPB does deliver a very reasonable estimation of the type and amount of work required, throughput/productivity, and cycle time (the time to complete a task and/or project). The benefit of a UPB is a significantly improved level of communication and understanding among project participants and stakeholders and full financial transparency. These benefits lead to fewer errors, omissions, change orders, and a virtual elimination of legal disputes.

A UPB may not reflect true costs or account for variances caused by weather, material availability, labor issues, security constraints, etc. for each project, but it does on average reasonably predict costs across multiple projects. In addition, a co-efficient, or multiple co-efficients can be used to account for any variables known in advance.

A Job Order Contract can range in sized from a few million to hundreds of millions of dollars. Individual projects or task orders are awarded, and additional and ongoing work is provided, or not-provided to the contractor based upon performance.

This “self-leveling” aspect provides the Owners a reasonable price for quality work (versus lowest price and questionable quality), and provides the Contractor with a reasonable profit. The contractor can provide a “fair” versus “high margin” price as many of the variables are better understood in a JOC situation.

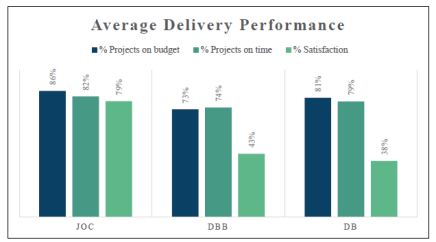

As the above chart shows, JOC outperforms both design-bid-build, and design-build. (Source – JOC Performance – Industry Study 2015 – ASU, PBRSG)

Job Order Contracting

The Basics of LEAN

The concept of lean rest on five (5) principles that when followed reduce waste and maximize value. These principles are:(i) Value specification: Precisely specify what creates value from the client’s perspective;(ii) Value stream identification: Clearly identify all the steps in the processes (value stream) that delivers exactly what the customer values and remove everything that do not add value to the customer;(iii) Flow: Take actions that ensure continuous flow in the value stream;(iv) Pull: This means to produce only what the customer wants just in time; and,(v) Perfection: Always strive for perfection by delivering what the customer wants and expects through a continuous removal of waste.